Property of sintered diamond

| Composition | C + binder |

|---|---|

| Structure | Sintered compact |

| Mechanical property | Tensile strength: 1.3GPa Bending strength: 1.1~2.6GPa Compressive strength: 6.9~7.6GPa Young’s modulus: 776~920GPa Hardness: HV 6,000~12,000 *Value for reference |

| Feature |

|

sintered diamond(PCD)

used in cutting by EDM machine

Sintered diamond (PCD) is a polycrystalline material by sintering diamond particles with metal binder at high temperature under high pressure. And it is made by cutting to a designated size out of a disc formed by diamond layer on a base of tungsten carbide.

As a size of single crystal diamond is limited, it is suitable in case a large area is required. Furthermore, conductive PCD makes EDM machining possible, and as its shape is relatively flexible, processing variant forms is possible, which is difficult for single crystal.

Date of processing sintered diamond

Sintered diamond

- Polish inner surface of hole of PCD

Roughness of inner surface of PCD four-sided hole: Ra0.0153

- Polishing up flat surface

Polishing flat surface: Roughness of the surface Ra0.0113

Sintered diamond – Examples of usage

-

Diamond wire drawing dies

-

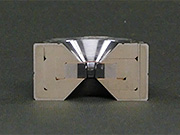

Diamond blasting nozzle

Basting nozzle which hole is made by sintered diamond with excellent wear and abrasion resistance.

-

Various tools

Adhesive nozzle, positioning nail, cutter, etc.