Since the company’s foundation in 1894, OGURA has been engaged in processing industry jewels. Jewel materials like diamond, sapphire/ruby are able to form a sharp edge as characteristic of single crystal.

By utilizing the property, OGURA has been providing products to meet current needs by keeping on brushing up micro precision technology.

Our strong technology of micro and precision perforation and processing tip-ends is able to make a sharp and higher precise shape.

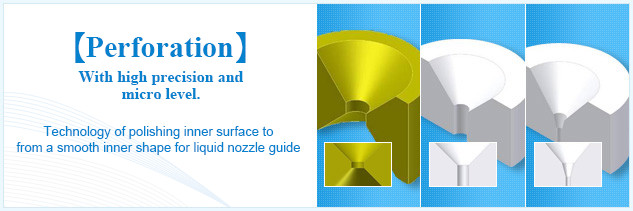

Perforation

Feature of perforation

- Inner diameter precision

Hole diameter: ±1µm and more. - Precision of hole:

circularity: 1µm and more.

- Size of Hole diameter:

φ30µm at minimum and more.

- Precision of polishing inner surface of hole:

Ra0.2µm and less. - Processing smooth inner surface to be used for guides and liquid nozzles.

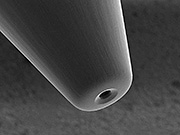

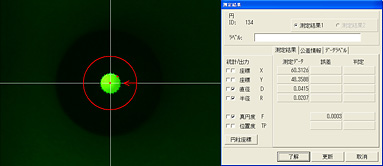

[Ruby] Perforation data

Ruby

Material:Single crystal ruby

Polishing a hole of micro diameter with high roundness.

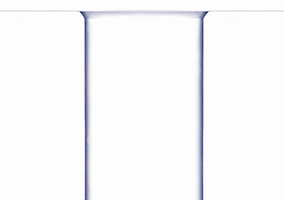

[Perforating ruby]

Hole diameterφ41.5µm

Circularity 0.3µm

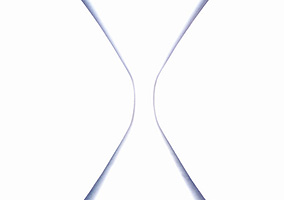

Image of perforation

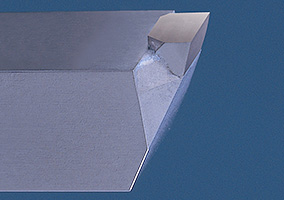

Cross section of perforating diamond

Cross section of perforating sapphire

Cross section of perforating tungsten

carbide

Cross section of perforating ceramics

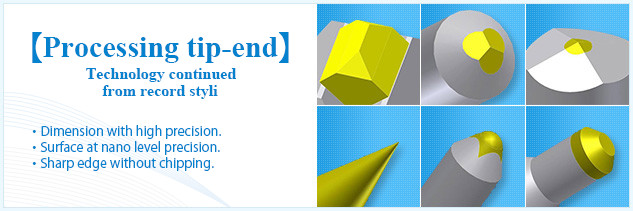

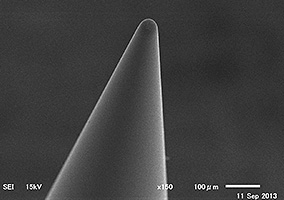

Processing tip-end

Features of processing tip-end

- Precision of tip-end R shape:

P-V=0.2µm and more - Precision of tip-end size: SR±1µm and more

- Tip-end R size: 1µm and less

- Polishing tip-end

Data of processing tip-end

Diamond

Materials: Single crystal diamond

Micro R shape

High precision of R shape

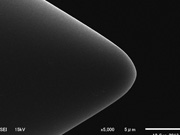

[Polishing diamond]

Tip-end R2.02µm

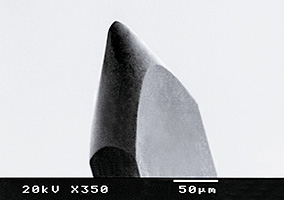

Image of machining tip-end

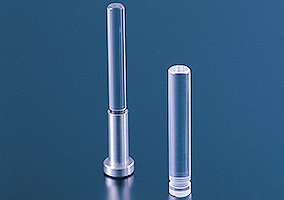

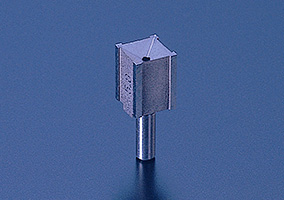

Diamond:Tip-end processing

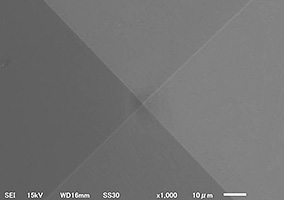

Diamond:Quadrangular pyramid

processing

Tungsten carbide:Tip-end processing

Diamond:Trigonal pyramid processing

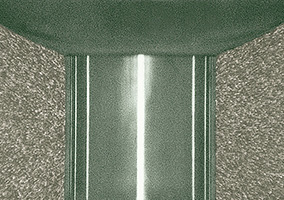

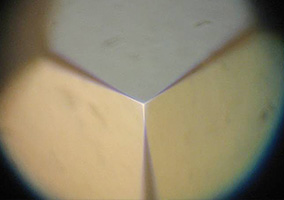

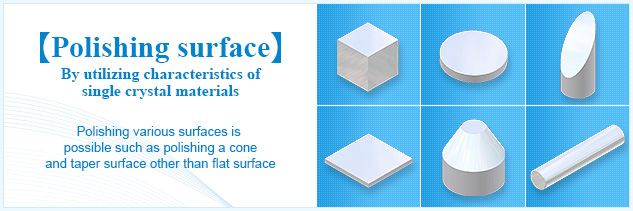

Processing surface

Features of processing surface

- Roughness of processing surface

Polishing Ra0.001µm and more (Reference: Depending of materials) - Roughness of processing surface of cylinder

Ra0.01µm and more (Reference: Depending on materials)

Data of processing surface

Sapphire

Processing to sufficient roughness level for a window of sensor.

[Processing flat surface]

Surface roughness Ra0.0064µm

Image of processing surface

Diamond:Polishing flat surface

Ceramics:Polishing flat surface

Sapphire:Polishing cylinder

Tungsten carbide:Polishing tapered

surface