Property of tungsten carbide

| Chemical composition | WC+Co |

|---|---|

| Structure | Sintered compact |

| Mechanical property | Tensile strength: 0.8 to 1.7GPa Bending strength: 2.4 to 2.6GPa Compressive strength: 6.1GPa Young’s modulus: 620 to 640GPa Hardness: HK 1,700 *Value for reference |

| Feature |

|

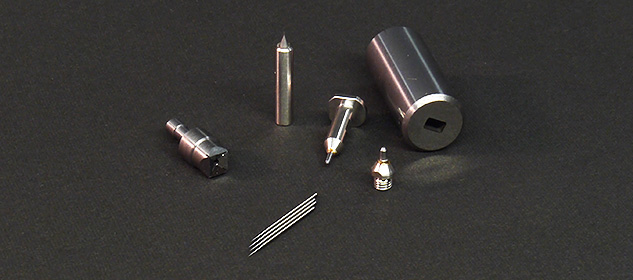

Examples of processed tungsten carbide

Tungsten carbide is a high versatile material used for metal molds, cutting machines, etc. OGURA is providing various tools with wear and abrasion resistance by machining tungsten carbide to various kinds of shapes.

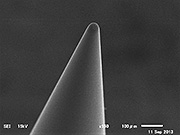

Especially, OGURA is good at machining smooth inner surface with good fluidity used as nozzles and dies. And we are able to polish up inner surface of holes with high precision diameter. What is more, we are also good at machining micro tip end just like push-up pins.

Processing tungsten carbide

Tungsten carbide

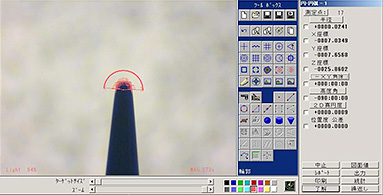

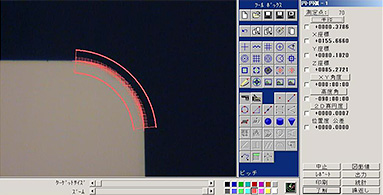

Very low variance of measurement of R at every corner of four-sided hole

- Measured value R1=R0.3786

- Measured value R2=R0.3787

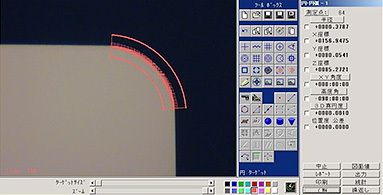

Tungsten carbide

Make tip-end R with 25µm ± 2µm

- Measure value of tip end: R=24.1µm

- Circularity of tip end: 0.9µm

- Polished to a beautiful cubic shape