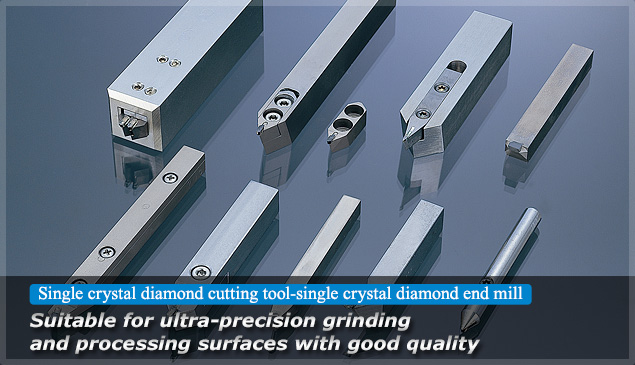

OGURA is providing single crystal diamond cutting tools and single crystal diamond end mill with a sharp edge suitable for processing precision parts, precision metal molds, etc., by making the most of technology of processing micro tip-end of single crystal diamond based on our long experience in producing record styli.

Higher precision and higher efficiency in machining work materials and processing cutting resistant materials are nowadays required in machining. In accordance with increase of needs of tools to fulfill the aforementioned conditions, market area is expanding where tools of single crystal diamond are demanded.

To cope with such needs, OGURA is designing and producing various cutting tools and end mills, are ready to design and produce customized tools to meet expanding needs.

Features

-

High-quality single crystal diamond is selected based on our long experience and used.

-

Enhanced quality and longer life using Laue X-ray reflection method for diamond orientation.

-

Diamond firmly coupled to shank for intermittent cutting.

-

Ultra-precision polishing of cutting tool edge for excellent sharpness

-

Separate shank and holder for quick setup and reduced machining time.

-

Shank and holder of tungsten carbide, stainless steel, other ferrous materials.

-

Various cutting tool designs for machine type, workpiece shape, machining conditions, operating condition, and intended use.

Single crystal diamond cutting tool

Straight cutting tool

Flat straight cutting tool suitable for micro cutting processing.Picture of the part of cutting edge.

Picture of the part of cutting edge

Superiority

- High precision of index of angle.

- Extra small undercut of cutting edge. Processing with less than 50nm is possible.

- Processing cutting edge with less than 1µm is possible.

Examples of usage

- 3 D micro machining with ultra-precision

- Cutting by ductility mode

- Metal molding of light-guide-display of liquid-crystal-display

- Metal molding of micro lens allay

- MEMS parts

- Various precision machining parts

R cutting tool

R cutting tool for precision molding and precision machining parts.

Picture of the part of cutting edge

Superiority

- Applicable for various precision machining of metal molding.

- Applicable to processing flat surface by enlarging R size for good cutting surface.

Examples of usage

- 3 D micro machining with ultra-precision

- Cutting by ductility mode

- Molding of light-guide-display of liquid-crystal-display

- Metal molding of pickup lens

- Metal molding of micro lens allay

- Mirror finished cut face of precision parts

Straight cutting tool with point corners

Cutting tool to form with complex shapes of cutting edges in accordance with customers' requests.

Photo of cutting edge

Superiority

- High accuracy of index of angle.

- Suitable for 3D micro machining with ultra–precision.

- Forming shapes of cutting edge with full customization.

Examples of usage

- 3 D micro machining with ultra- precision

- Cutting by ductility mode

- MEMS parts

- Various precision machining parts

Special cutting tool

Cutting tools produced with full customization.

Diamond cutting tool for simultaneous machining

Burnishing tool

Superiority

- By setting 2 kinds of R cutting tools and adjusting position of cutting edge with high precision, high efficient cutting is possible.

- By setting 2 kinds of straight cutting tools and adjusting position of cutting edge with high precision, high efficient cutting and high pitch accuracy as well.

- Used as a burnishing tool for well finished surface.

Examples of usage

- Precision machining of flat surface with high precision

- Cutting with high efficiency

- Finishing of various precision parts

Diamond end mill for 3D micro machining with ultra-precision

Ball end mill, end mill for V-groove processing.

Single crystal diamond ball end mill

Superiority

- No incomplete cutting because of less position-shifting against the center of rotation.

- Suitable for 3D micro machining with ultra-precision.

Examples for usage

- 3D micro machining with ultra-precision

- Micro lens allay metal molding

- Various precision machining of parts

- MEMS parts